Lowering the RA value of circular sealing surfaces

The plastics machining company of the Netherlands is not a title you can just give yourself. Within BKB Precision, we are therefore always busy improving and innovating our plastics machining techniques. For example, we have recently been busy reducing the RA value of C-faces by 50% thanks to a completely new and self-designed technique.

The problem

To prevent leakage when fitting O-rings, it is essential to keep the surface roughness (RA value) as low as possible. We recently started a pilot project with a customer to further reduce this RA value and minimize the risk of scratching, so that the sealing surfaces of the O-rings are guaranteed to remain leak-free.

The challenge here is that during milling, the tool inevitably comes to a stop on the product, which can result in a slightly higher RA value or small scratches on the sealing surface, which can cause leakage. At BKB Precision, however, we don't shy away from any challenge. We have been fully committed to making this improvement possible.

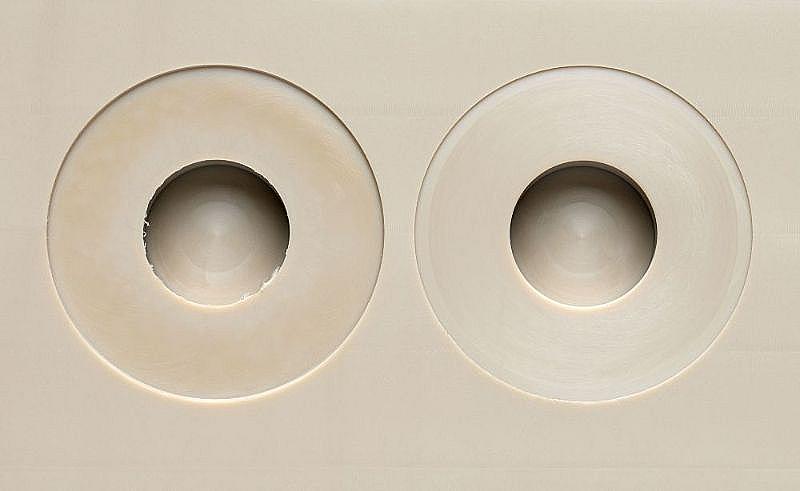

The circular sealing surfaces

We performed several tests to reduce the RA value, and successfully. First, we milled the sealing plane with a C router, then machined the surface with a custom-made brushing tool in the machine. This left the dimensions unchanged, while significantly reducing the RA value.

Whereas before we had to do a lot of sanding to meet strict RA values, we have now automated this process which brings several advantages. For example, we have been able to reduce RA values by 50% and increase the guarantee of leak-free circular sealing surfaces. In addition, this new technique is more cost-effective, reliable and time-saving. Whereas we used to spend 4-5 minutes meeting the RA values of one sealing plane, this automation means we are down to 22 seconds.

So what makes this so complicated?

After extensive testing, measuring, consultation and feedback, we managed to overcome this challenge. With the knowledge and expertise we have in the field of plastics machining, we have developed a completely new technique and associated tools to make this pilot a success.

As a result, all of our customers will benefit from this new technique. The technique is applicable to all types of plastics and we will of course continue to work on optimizing this operation. From now on, this technique can be used for all C-faces that we will produce in the future.

Curious to learn more about this new machining method or what this means for you?

Wondering what this newly developed technique means for you? Or would you like to learn more about how this machining really works? We are happy to share our knowledge with you. Feel free to contact one of our specialists and we will be happy to help you.