The power of PEEK - the high-performance material for precision applications

Not every material is suitable for applications where extreme conditions are the norm. High temperatures, aggressive chemicals and mechanical wear can limit the performance of plastics. PEEK offers a solution here thanks to its exceptional properties. But what makes PEEK such a unique material, and how do you get the most out of machining processes?

The strength of PEEK

What exactly makes PEEK so unique? This high-performance polymer combines the strength and wear resistance of metals with the flexibility and light weight of plastics. Whereas traditional plastics like PVC or PP deform quickly at high temperatures, PEEK retains its strength and structural integrity even under extreme conditions

Compared to metals, PEEK offers not only weight savings, but also better resistance to corrosion and chemical attack. This combination of properties makes it an indispensable material in high-tech applications where precision and durability are paramount.

Precision in PEEK machining: complex, but our expertise

Machining PEEK seems simple at first glance, but it presents specific challenges. Due to its toughness and wear resistance, high friction occurs during turning and milling, which can lead to heat generation and deformation. This requires precise cutting parameters and special tools to keep the machining process stable.

To achieve tolerances down to the hundredth of a millimeter, a perfectly balanced process is essential. Finishing also plays a crucial role: the wrong milling strategy can lead to a rough or damaged surface.

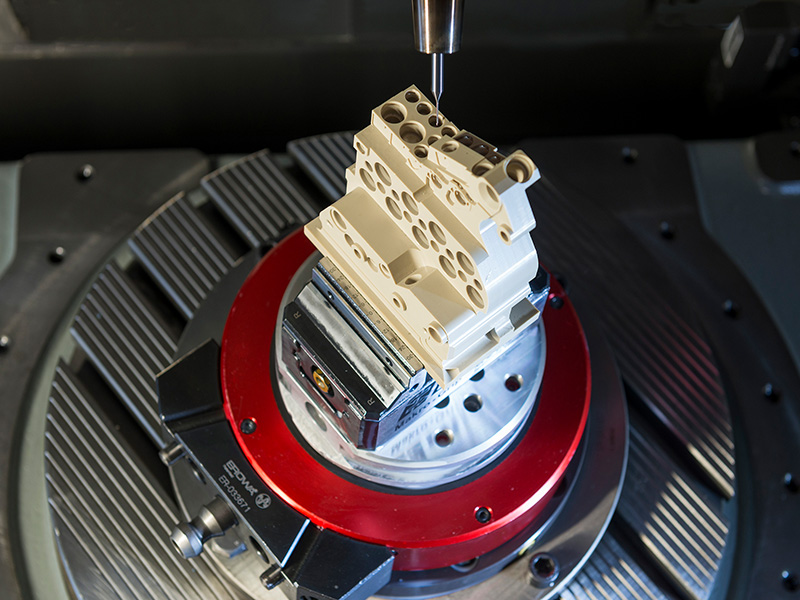

How do we tackle this? At BKB Precision, we combine advanced machinery, specialist knowledge and strict process control and ensure an optimal end result every time.

Advanced machinery with specialist knowledge and process control for a perfect end result. Not for nothing is PEEK the most frequently machined material in our workshop.

Why choose PEEK? The most important advantages

PEEK is a material that has proven itself in demanding industries. The main advantages for choosing this material are:

- High temperature resistance up to approximately 280 °C

- High wear resistance

- Despite the strength of the material, it is lighter than many metals

- Resistant to many corrosive substances

- Biocompatible

PEEK in the world of high-tech applications

PEEK is a crucial material, especially for the medical and semicon industries, where reliability and precision are vital. In the medical industry, PEEK is widely used for implants and surgical instruments, increasingly replacing metals. This is because PEEK is more body-friendly and more resistant to wear.

In the semicon industry, PEEK is an ideal choice for applications that operate under extreme conditions. Among other applications, the material is used for connectors and insulators where thermal stability and chemical resistance are essential. PEEK offers reliable performance in the production of semiconductor components that have high demands for accuracy and reliability.

View several practical examples to the right or feel free to contact us with any questions!

Do you have questions about PEEK? We'd love to help!

Do you have specific questions about PEEK or want to know how it can be applied in your industry? Our experienced team would be happy to help. Contact us for personal advice and the best solutions for your projects!