Laser marking of plastics

There is a growing need in the manufacturing industry to identify or permanently mark products. As a result, laser marking has become increasingly popular. This technique is used mainly on tools and components for the purpose of identification; this is also true with plastic processing.

Incidentally, plastics are more difficult to laser mark than steel. If laser marking is not possible, traditional engraving might be a good alternative. Do you want to know what the possibilities are? Then don’t hesitate to get in touch.

What is laser marking?

Laser marking is a relatively new technique. A computer controls the laser beam which can create an image, text or code on plastic, organic material, or metal. A laser mark is accurate, highly durable, and almost imperceptible to touch. We expect this technique to partially replace laser engraving.

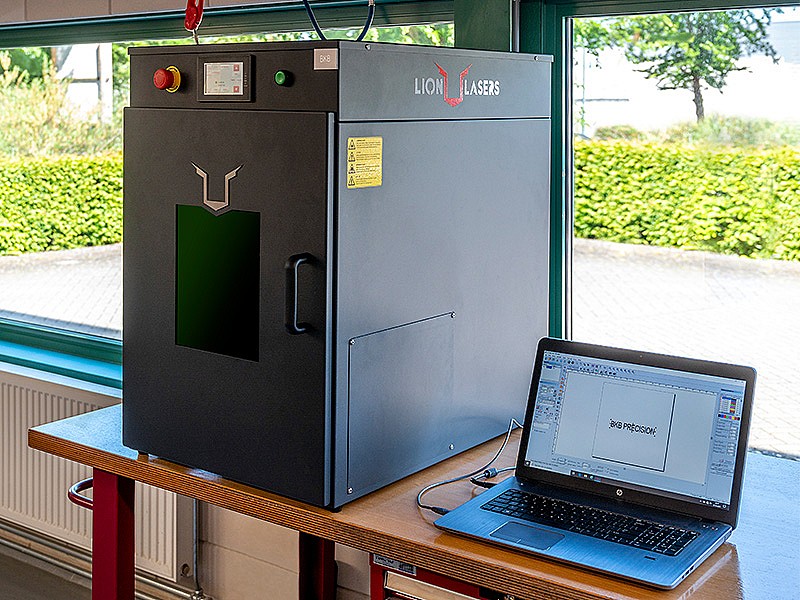

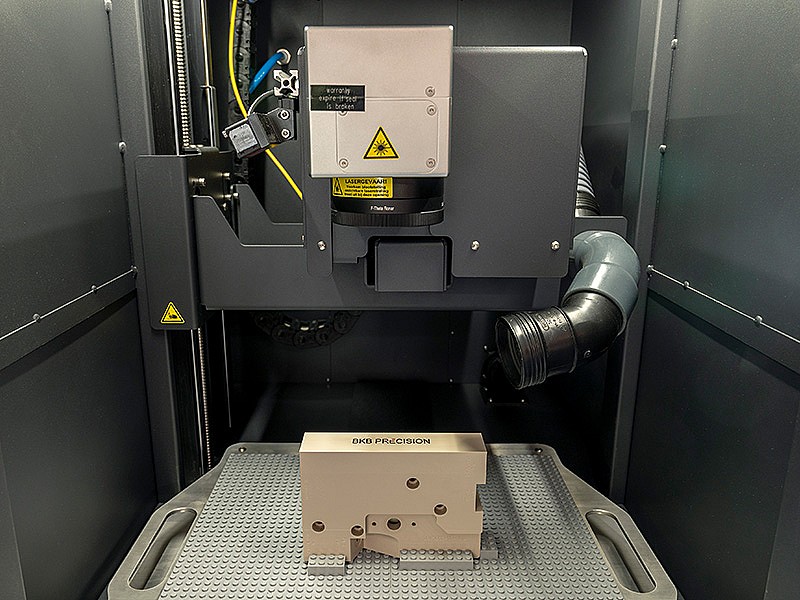

BKB Precision uses the Lion UV 3W, a laser machine from Lion Laser Systems, which is capable of marking around cylindrical products. ‘This machine is a fine addition to the product engraving which BKB Precision already does,’ says director Mannes Westhuis. ‘We can now offer even more customisation and service to our customers, as well as being able to mark our own materials.’

This machine is a fine addition to the product engraving which BKB Precision already does. We can now offer even more customisation and service to our customers, as well as being able to mark our own materials', says director Mannes Westhuis.

Laser marking with LionFiber

At BKB Precision, we have opted for the LionFiber machine, a solidly housed piece of equipment with user-friendly touchscreen operation and software. Thanks to its short set-up times and flexibility, it is also possible to laser mark a small series.

This laser marker is versatile and fast-working. We can use it to mark or personalise products permanently and accurately. Whether you want a sleek logo, barcodes, or product and serial numbers – it’s all possible.

BKB Precision also uses the laser marker to mark the special machine tools we use for our precision plastic processing. By distinguishing complex machine tools, we can make automatic tool distribution even more efficient.

Types of plastic

It is possible to permanently laser mark almost all types of plastic. Some plastics suitable for this are shown below:

- Polyamide (PA)

- Polycarbonate (PC)

- Polypropylene (PP)

- Polyoxymethylene (POM)

- Polyarylsulfone (PSU, PPSU)

- Polyetherketone (PEEK)

- Polyiamide (PI)

- Polymethyl metacrylate (PMMA)

- Polyethylene terephthalate (PET)

Would you like to know more about laser marking?

If you are curious to see whether it might be interesting for your product, please contact one of our specialists.